Case Study - GWA Group Limited

Stretch Wrap Usage Reduced by 182 Skips Bins

Annual Cost Saving

Stretch Film Reduction

Client:

GWA Group Limited was listed on the Australian Stock Exchange in 1993. GWA is a leading Australian supplier of building fixtures and fittings to households and commercial premises. The Group has sales and distribution facilities located across Australia and a branch office in New Zealand.

GWA Bathrooms & Kitchens is Australia’s foremost designer, importer and distributor of iconic brands and products, servicing and enhancing residential and commercial bathrooms and kitchens across Australia and New Zealand. The product range is distributed under market leading brands including Caroma, Methven, Dorf and Clark.

The Problem:

The industry has been a stagnant, stretch film was previously only available in 20 to 25-micron thickness with very low stretch yield and strength. Tonnes and tonnes of unnecessary plastic waste accumulates in landfill each year due to old fashion and inefficient pallet wrapping methods.

Before Omni approached GWA Group with the ‘Perfect Pallet Wrapping Solution’, they were unaware of how much money and plastic they are wasting with low performance stretch wrap.

Key Problems:

-

724 grams of film used to wrap each pallet

-

52,128kg of stretch wrap used per year

-

Stretch wrap breakages causing downtime

-

Wrapping costs were high and increasing

The Challenge:

GWA Group were severely over wrapping their pallets. When Omni approached them, significant stretch wrap savings were obvious. GWA Group were using 25um stretch film on pallet wrapping machines that didn’t have a power pre-stretch capability. They were using over 52 tonnes of plastic pallet wrap per year.

Previous Pallet Wrapping Method

Stretch Wrap Usage = 52,128kg (Per Year)

The Solution:

The Omni Pallet Wrapping Machines and Omni Stretch Wrap was the perfect solution for GWA Group. After conducting several load containment, film puncture and plastic usage tests, Omni Group were pleased to present significant environmental and financial savings.

Solution Summary

Stretch Wrap Usage = 15,840kg (Per Year)

-

access ramps.Omni Base Pallet Wrapping Machine with power pre-stretch scales & auto cut off

-

Stretch film usage reduced 69.6% - from 724gm to 220gm

-

Stretch film cost reduced by $82,800/year

-

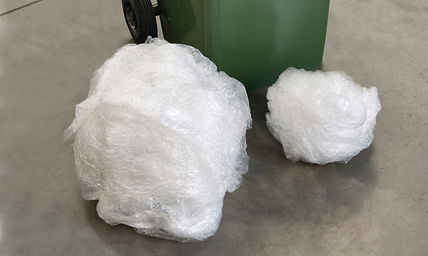

Stretch wrap usage reduced by 182 Skips Bins

The Results:

The implementation on the Omni Pallet Wrapping Solution provides astounding financial and environment benefits. A 69.6% stretch film reduction is equivalent to over 36.3 tonnes of film per year. This volume of stretch film would fill 182 skip bins every year. By increasing their stretch film efficiency GWA saves over $79,200 per year.

Not only did they significantly reduce pallet wrapping costs and carbon foot print, they increased their warehouse efficiency. One roll of Omni Stretch Wrap can wrap 52 pallets which is more than double the amount of the conventional stretch wrap. Less roll changes means less pallet wrapping downtime.

“Omni Group’s philosophy is to exceed our clients’ expectations and to do more than they ask or think. Giving you what you want is our priority but exceeding what you even thought is our goal.”

Total Savings Per Year

$79,200

Cost Saving on Stretch Wrap

48.9%

Cost Saving on Stretch Wrap

36,288kg=

Stretch Wrap Usage Reduction =

69.6%

Roll Changes Reduced by

Stretch Wrap Usage Reduction=

182 Skip Bins