Case Study - BevChain

Stretch Wrap Usage Reduction 10524 kg

Annual Cost Saving

Stretch Film Reduction

Client:

BevChain operates from 25 distribution centres in 6 states, with a fleet of over 200 vehicles plus sub-contractors. Handling in excess of 2.5 billion serving units annually and calling on 25,000 delivery points, BevChain are the leaders in beverage supply chain solutions.

As a specialist in the warehousing & distribution of alcoholic beverages, BevChain understands the demands placed on the liquor industry & its customers. Since BevChain’s inception, suppliers of beer, wine and spirits have all taken advantage of BevChain’s specialised services and our ability to tailor solutions to meet their needs.

The Problem:

Before Omni approached BECHAIN with the ‘Perfect Pallet Wrapping Solution’, they were unaware of how much money and plastic they are wasting with low performance stretch wrap. There were also other problems they have which they were aware of but couldn’t find a solution.

Key Problems:

-

191 grams of film used to wrap each pallet

-

16,044kg of stretch wrap used per year

-

Stretch wrap breakages causing downtime

-

Wrapping costs were high and increasing

The Challenge:

BECHAIN was severely over wrapping their pallets. When Omni approached them, significant stretch wrap savings were obvious. The challenge was to achieve maximum savings, they needed a new pallet wrapping machine. With pallet wrapping expenses already too high, this extra capital expenditure wasn’t allowed for.

Previous Pallet Wrapping Method

Stretch Wrap Usage = 16,040kg (Per Year)

The Solution:

The Omni Euro Cast Machine Stretch Wrap was the perfect solution to BECHAIN’s pallet wrapping problems. After conducting several load containment and stretch film usage tests, Omni Group were pleased to present huge environmental and financial savings as well as significantly increasing wrapping efficiencies.

Solution Summary

Stretch Wrap Usage = 16,040kg (Per Year)

-

Award winning Euro Stretch Wrap

-

Roll changes reduced from 10.4 per day to 5.3

-

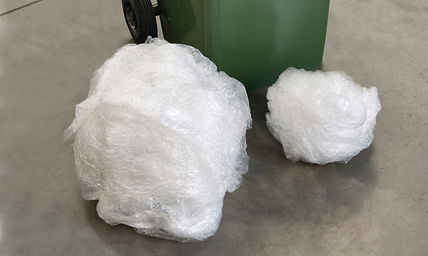

Film reduction equivalent to 52 skip bins per year

-

Stretch wrap puncture force of increased by 300%

-

Stretch film cost reduced by $27,066/year

The Results:

The implementation on the Omni Pallet Wrapping Solution provides astounding financial and environment benefits for GWA Bathrooms & Kitchens. A 69.6% stretch film reduction is equivalent to over 36.3 tonnes of film per year. This volume of stretch film would fill 182 skip bins every year. By increasing their stretch film efficiency GWA Bathrooms & Kitchens save over $79,200 per year.

Not only did they significantly reduce pallet wrapping costs and carbon foot print, they increased their

warehouse efficiency. One roll of Omni Stretch Wrap can wrap 52 pallets which is double the amount of the conventional stretch wrap. Less roll changes means less pallet wrapping downtime.

“Omni Group’s philosophy is to exceed our clients’ expectations and to do more than they ask or think. Giving you what you want is our priority but exceeding what you even thought is our goal.”

Total Savings Per Year

$27,066

Cost Saving on Stretch Wrap

52.8%

Cost Saving on Stretch Wrap

10,524kg=

Stretch Wrap Usage Reduction =

65.6%

Roll Changes Reduced by

Stretch Wrap Usage Reduction=

52 Skip Bins